Products

Deboom Energetic Graphene Anti-Wearing Diesel Engine Oil Additive for Logistic Trucks, Construction Machines, Buses

How Energetic Graphene Works?

Friction and wearing between mechanical parts widely exist in mechanical systems. Engine is the same. Friction consumes a lot of energy, and wearing will lead to premature failure of parts. In order to improve the service efficiency and life of engine, friction and wearing between parts must be reduced. Lubrication technology is the key technology to solve friction and wearing, prolong the service life of engine and improve the fuel consumption efficiency.

Graphene is a one-atom-thick layer or a few layers of carbon atoms arranged in a hexagonal lattice. With this special structure, graphene has properties of small friction coefficient , good chemical & physical stability and mechanical performance.Graphene is regarded as the king of new material and the amazing material which will change the 21st century.

It’s ideal nanomaterial to improve tribological performance. It enhances the lubricating properties of base engine oil. When engine is started, graphene nano particles enable penetration and coating of wear crevices (surface asperities) forming a thin protective layer between metal parts of moving pistons and cyliners.Due to the very small molecular particles of graphene, it can generate a ball effect during friction between the cylinder and the piston,transforming sliding friction between metal parts into rolling friction between graphene layers. friction and wearing are greatly reduced and powder is enhanced, consequently saving the energy and improving the fuel consumption efficiency. Besides, during the circumstance of high pressure and temperature, graphene will attach onto the metal surface and repair the wearing of the engine(carburizing technology), which will prolong the engine service life. When engine works efficiently, the carbon and other toxic emission to the environment is reduced and noises /vibrations will decrease consequently.

Timken Friction Test

Test shows the friction is greatly reduced and the lubricating effect is significantly improved after energetic graphene is used in the oil.

Application

Various vehicles with diesel engine.

Certificates

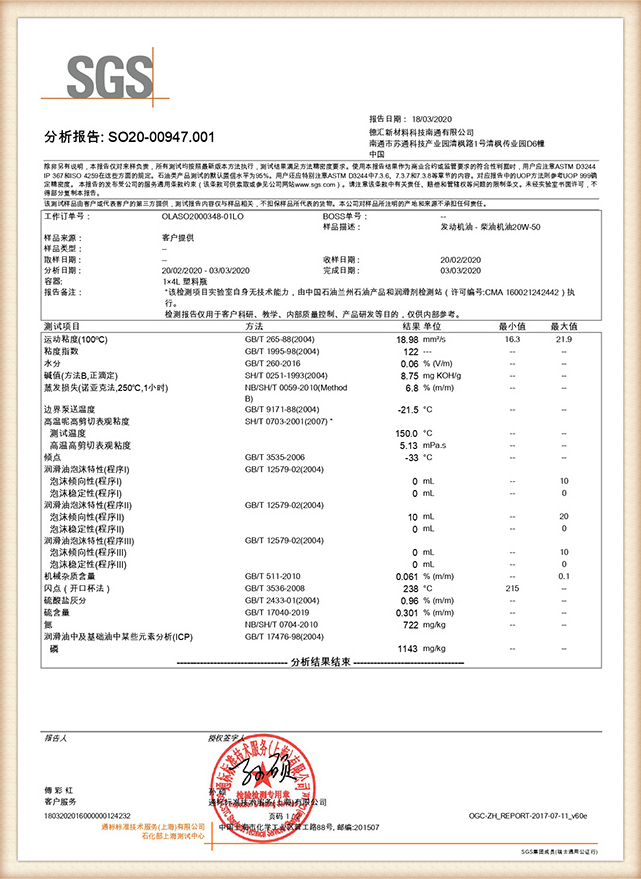

CE, SGS, CCPC

Why Us?

1.29 Patents Owner

2.8 Years' Research on Graphene

3.Imported Graphene Material from Japan

4.The Sole Manufacturer in the Industry of China

Obtaining the Transportation Energy Saving Certification

Frequently Asked Questions

1.Are you manufacturer or trading company?

We are a professional manufacturer of graphene engine oil additive.

2.How long has your company been in this industry?

We have been in the research,manufacturering and sales for more than 8 years.

3.Is it graphene oil additive or graphene oxide additive?

We use purity 99.99% 5-6 layer graphene, which is imported from Japan.

4.What is MOQ?

2 bottles.

5.Do you have any certificates?

Yes, we have CE,SGS, 29patens and many certificates from China top testing agencies.